High chrome white iron -ASTM A523 Series

Why it has good performance

For years, we've been dedicated to abrasive-resistance materials research and practice, a series of high-chrome ironmaterials were born in the lab and have been put into the market.

The reason high-chromium cast iron possesses exceptional wear resistance is that its matrix is composed of martensitewithin which metallic carbides are dispersed.

By employing diferent smelting, casting, and heat treatment processes, the materia's properties are further optimized.The distribution and shape of carbides are tallored to meet the demands of varying applications, resulting in distinct wearresistance, corrosion resistance, and impact resistance performance to meet different working reguirements.

Why ours different

Due to differences in chromium and other componentcompositions, as well as variations in casting processessuch as pouring temperature and method, there are significant differences in the final microstructures of thetwo materials. Such differences are more pronounced in the practical applications,especially in terms of servicelife.

Material list

Material list

OUR SUCCESSFUL CASE

Baseline

Our solutions

Our solutions

- A leading iron ore plant faced severe wear issues in their slurry pump wet parts (impellers, liners) due to handling large (2-4mm), sharp, and highly abrasive particles at 960 RPM. The original high-chrome white iron components lasted only 300 hours under these harsh conditions.

Our solutions

Our solutions

Our solutions

- Material Innovation: Redesigned the alloy composition of high-chrome white iron (e.g., optimized Cr/C/Mo ratios) to enhance wear resistance while maintaining critical impact toughness. The micro-structure contains rod-shape carbide and martensite matrix, refer to the picture below, the abrasion performance of the bar shape carbide is superior than cellular shape carbide in some extent.

- Lab Validation: Conducted rigorous abrasion testing and impact tests

- Field Performance: Achieved a 480-hour service life in operational trials, extending component longevity and reducing downtime.

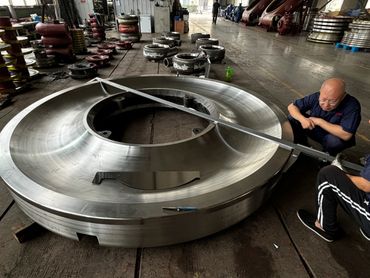

OEM PUMP PARTS MADE BY SOLID FOUNDRY

Contact us for pricing, factory, products details!

Where there are tough tasks, where Foundryman goes!

Hebei Foundryman Technology Co., Ltd

Copyright © 2020 Hebei Foundryman Tech- All Rights Reserved

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.